Stainless Steel Sheets

- Home

- Stainless Steel Sheets

Product

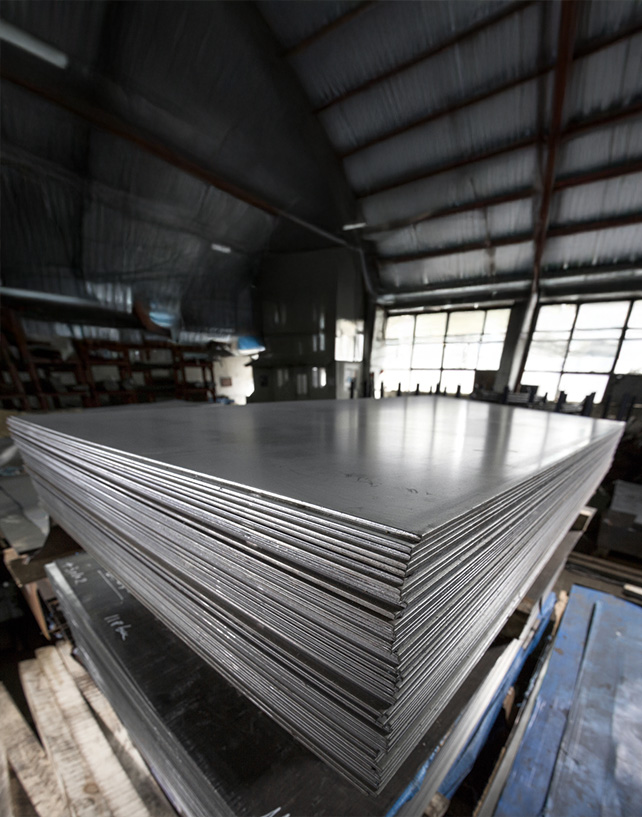

Stainless Steel Sheets Manufacturer, Supplier and Stockist

Navnidhi Steel is a trusted name in the stainless steel industry, delivering high-quality stainless steel sheets that meet global standards. As a leading manufacturer and supplier,we provide sheets that combine durability, strength, and aesthetic appeal. As a Supplier of stainless steel ,Our stainless steel sheets are widely valued for their excellent resistance to corrosion, oxidation, and heat, making them an ideal choice for industries where reliability and performance are critical. With precision engineering and strict quality control, our sheets offer both long-lasting utility and visual elegance.

At Navnidhi Steel, we believe stainless steel is more than just a material. It’s the foundation of durability and innovation. Our stainless steel sheets are available in a variety of grades, thicknesses, and finishes, ensuring suitability for diverse applications ranging from construction to high-tech industries. With a strong footprint in both Indian and international markets, Navnidhi Steel continues to be a preferred supplier of stainless steel solutions worldwide.

Comprehensive Specification Chart

| Thickness | 0.1mm to 10mm |

|---|---|

| Width | 8mm to 2500 mm |

| Standard | AISI, JIS, SUS, GB, ASTM A240 and AMS |

| Surface Finish | Brushed, Polished, Embossed, BA, 2B, 2BA, 8K, NO.4, HL, SB, NO.1, 2H |

| Edge Condition | Mill Edge or Trimmed Edge |

Steel Type & Grades

| Ferritic Steel | 405, 409, 409M, 409Ti1, 409Ti2, 410S, 410S1, 410S2, 410S3, 429, 429Nb, 430, 430Ti, 430Ti1, 434, 436, 436L, 409L, 436L1, 439, 439Ti1, 439Ti2, 441, 442, 443, 444, 445, 445L1, 44512, 446S1, 446S2, 446S3 |

|---|---|

| Austenitic Steel | 301, 301L, 301LN, 302, 304, 304L, 304H, 304LN, 304N, 304Cu, 304Mn1, 304Mn2, 304N2, 304Nb, 305, 305Cu, 309, 309S, 309H, 309Nb, 309HNb, 310, 310S, 310H, 310N, 310Nb, 310HNb, 310MoLN, 312, 316, 316L, 316H, 316LN, 316Ti, 316Nb, 316N1, 316N2, 317, 317L, 317LM, 317LMN, 317LCu, 317LN, 321, 321H, 326, 334, 345, 347, 347H, 347LN |

| Martensitic Steel | 403, 410, 451, 420, 420S1, 420S2, 420S3, 431, 440 |

| Duplex Steel | 1803, 2011, 2012, 2013, 2101, 2205, 2304, 2441, 2507 |

Stainless Steel Sheet Classifications Based on Material

Austenitic stainless steel

These are the most widely used type, containing high chromium and nickel with low carbon. They are non-magnetic, highly resistant to corrosion, and known for their toughness and formability. These sheets perform well in extreme temperatures and are commonly used in chemical plants, food-grade equipment, pipelines, and architectural designs. Popular grades include 304, 304L, 316, and 321.

Ferritic stainless steel

Ithas moderate chromium levels and little or no nickel, making them cost-effective and magnetic. They provide good resistance to oxidation and stress corrosion, though with lower ductility than austenitic grades. Due to their heat resistance and durability, ferritic sheets are used in automotive exhausts, household appliances, and interior architecture. Grades like 409, 410S, 430, and 446 are widely applied.

Martensitic stainless steel

Itcontain higher carbon along with chromium, giving them excellent hardness and strength, especially after heat treatment. While their corrosion resistance is lower compared to austenitic or duplex types, their wear resistance makes them suitable for tools, blades, turbines, valves, and surgical instruments. Common grades include 410, 420, 431, and 440.

Duplex stainless steel

Itcombines the properties of austenitic and ferritic steels, offering high strength and superior resistance to stress corrosion cracking and pitting. Their balanced composition of chromium, nickel, and molybdenum makes them ideal for marine, offshore, chemical, and paper industry applications. Grades like 2205 and 2507 are frequently used.

Advantages of Stainless Steel Sheets

Outstanding resistance to corrosion, oxidation, and high temperature

High strength and durability for long-term use

Low maintenance and easy to clean

Variety of attractive surface finishes for decorative use

Excellent formability, weldability, and fabrication properties

Eco-friendly and fully recyclable

Hygienic, making them suitable for food and medical environments

Applications and Uses of Stainless Steel Sheets

Construction & Infrastructure

Widely used in cladding, roofing, wall panels, and elevators for strength, durability, and modern aesthetics.

Automotive Industry

Applied in body panels, trims, and exhaust components where corrosion resistance and long service life are essential.

Food & Beverage Processing

Ideal for kitchen equipment, storage tanks, and machinery due to their hygienic surface and easy cleaning.

Chemical & Petrochemical

Used in tanks, heat exchangers, and pipelines because of their superior resistance to chemicals and heat.

Pharmaceutical & Medical

Preferred for surgical tools, cleanroom surfaces, and equipment housings to maintain sterile environments.

Energy & Power

Essential in solar panels, wind turbines, and power plant components where strength and heat resistance are critical.

Marine & Offshore

Excellent choice for ship structures, docks, and offshore rigs, as they can resist seawater corrosion effectively.

Household Appliances

Found in refrigerators, ovens, and washing machines, combining durability, sleek design, and low maintenance.

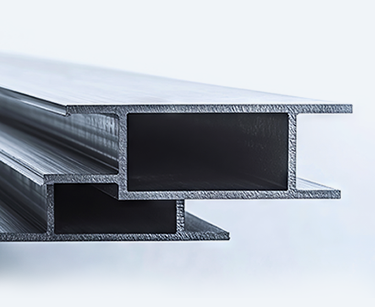

Stainless Steel Sheets Edge Options

We offer stainless steel sheets with Mill Edge (cost-effective, untreated edge) and Trimmed Edge (smooth, precise edge) to meet diverse manufacturing and finishing needs.

Cost-Effective, Raw

Mill Edge

Untreated edge from the rolling process, ideal for general-purpose use.

Precision, Smooth

Trimmed Edge.

Processed edges for cleaner cuts and accurate applications.

Two Options, One Solution

Flexible, Reliable

Choose the right edge finish to match your manufacturing needs.

- Precision Metal Works

- Building with Steel

- Crafting Metal Mastery

- Precision Metal Works

- Building with Steel

- Crafting Metal Mastery

- Precision Metal Works

- Building with Steel

- Crafting Metal Mastery

- Building with Steel

- Precision Metal Works

- Crafting Metal Mastery

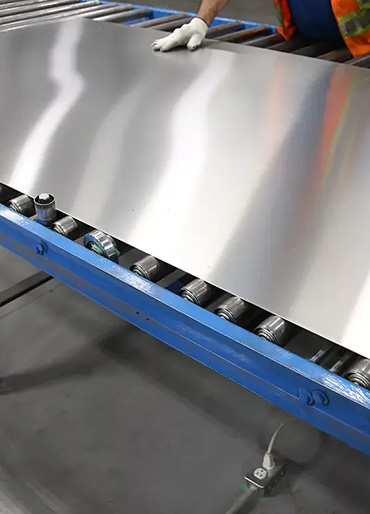

Delivery

Leaders in Precision [Manufacturing]

Safe, Secure, On-Time

We ensure every stainless steel coil reaches customers in excellent condition. Packed with industry-standard materials to resist moisture, dust, and damage during storage and transit.

With every order, we guarantee safety, reliability, and peace of mind.

Hemant Jain

CEO & MD

100%

Damage-Free Guarantee

Our Purpose

To deliver stainless steel coils safely, maintaining product integrity from dispatch to delivery.

Our Values

Packaging and handling that protect, so our customers receive complete confidence in every shipment.

Why Choose Stainless Steel Sheets by Navnidhi Steel

With years of experience, we deliver reliable stainless steel solutions tailored to diverse industrial applications.

Our slitting coils are manufactured using premium stainless steel for strength, durability, and corrosion resistance.

We provide coils slit to precise widths, ensuring accuracy and flexibility for specific customer requirements.

Every coil undergoes strict testing to maintain dimensional accuracy, consistency, and superior performance.

With strong logistics, we ensure safe packaging and on-time delivery across India and international markets.

Our expert support team ensures smooth project execution and long-term customer satisfaction.

Navnidhi Steel

Contact

Office Address : Navnidhi Steel LLP , 1 Lehari Mansion 236/240 Svp Mumbai- 400004

Plant / Factory Address : Navnidhi Steel LLP ,Plot No. D 001, Lodha Palava Industrial area, Taloja - Ambernath Road. Usatane - 421204.

Useful Links

Let’s Connect

- Stainless Steel Coils

- Stainless Steel Sheets

- Stainless Steel Slitting Coils

- Stainless Steel Plates

- Stainless Steel Flanges

© 2025 All rights reserved.Metalbulls ![]()

Error: Contact form not found.